Our Main Services

Additional Services

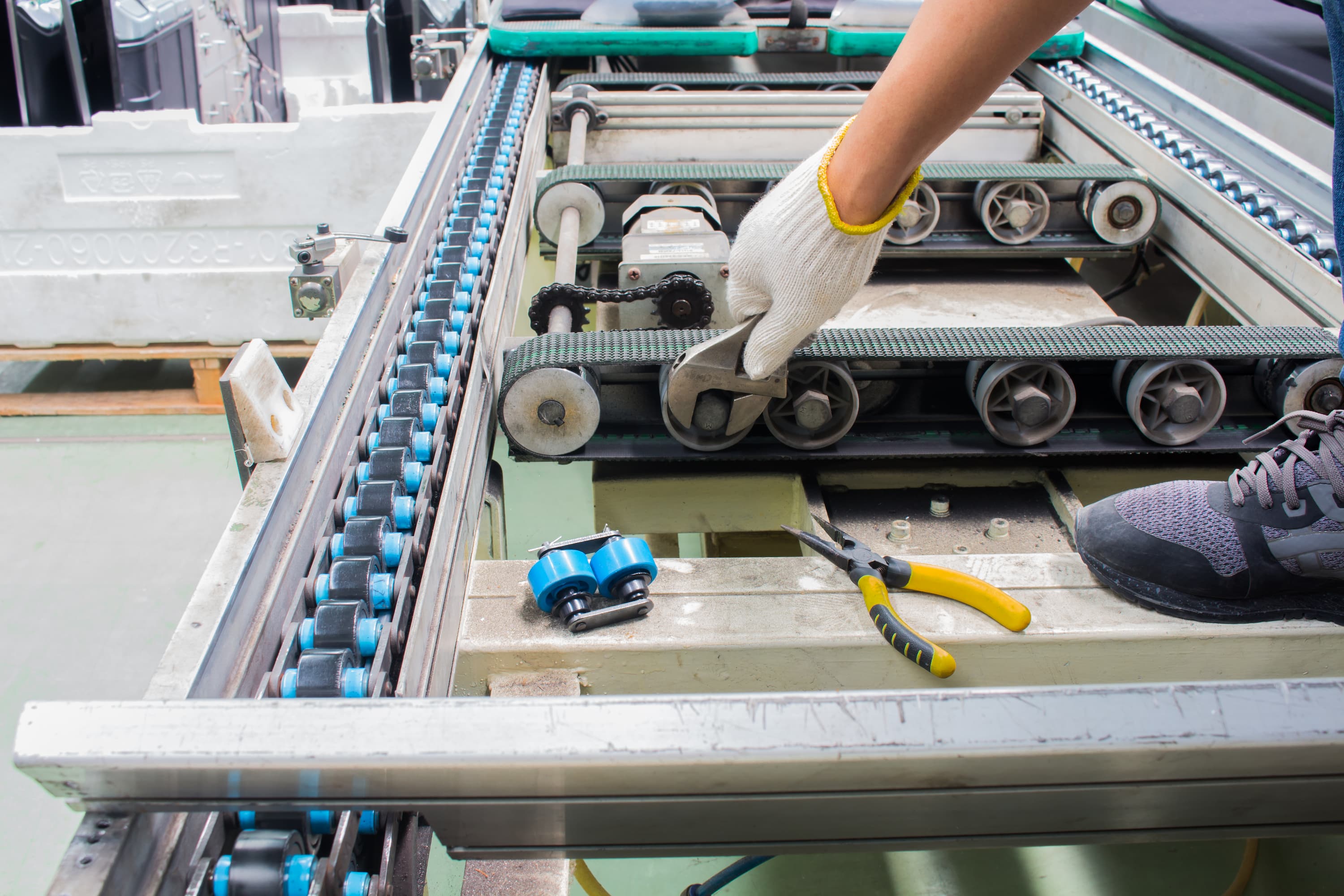

Mechanical and Electrical Maintenance

Gap Engineering offer a professional maintenance service, which through consultation with our clients is dedicated to improving plant reliability, efficiency and cost reduction. Our advice is always based on sharing best practice drawing on 40 years experience of developing bespoke effective maintenance packages for our clients.The main features of our maintenance service are :

- Maintenance planning and inspection service

- Provision of qualified engineers

- Bespoke site teams

- Breakdown service

- Shutdowns and shift cover (long and short term)

- Daywork and contract pricing options

- Single point contact for service back up

- Condition and energy monitoring advice/services

Machince Assembly

From the initial planning and consultation Gap Engineering can provide the complete Machine Assembly package, from risk assessment and method statement to the moving, lifting, transporting and reinstallation of your equipment - We will manage every aspect of the works undertaken.Machince Relocation

From the initial planning and consultation Gap Engineering can provide the complete Machine Relocation package, from risk assessment and method statement to the moving, lifting, transporting and reinstallation of your equipment - We will manage every aspect of the move.Shutdown Work

Regular maintenance and servicing of plant and machinery is essential for successful companies if they are to maintain productivity.- Gap Engineers can work independently or as an integral part of your in house maintenance team during production shutdowns.

- Gap Engineers will complement your team to ensure all work is completed on time and within budget.

Projects

- Gap Engineering offers a full support service

- Provision of qualified engineers

- Bespoke site teams

- Breakdown service

- Shutdowns and shift cover (long and short term)

- Daywork and contract pricing options

- Single point contact for service back up

- Condition and energy monitoring advice/services

Condition Monitoring

- Condition monitoring is a technique that allows the implementation of a cost effective predictive maintenance regime

- Gap Engineering can provide advice on a number of low cost condition monitoring solutions which have been proven to deliver major savings on maintenance and dramatically reduce downtime and critical failures

Energy Monitoring

- In today's energy and environmentally conscious economy it is vital for businesses to have a clear picture of their energy consumption. Reducing wasted energy, reducing energy bills and optimising use of resources are all key to an effective energy and resource management policy

- Gap Engineering can provide advice on completely independent utility metering or sub-metering solutions, delivered through a fully automated meter reading service. The system can collect energy data from a wide variety of sources, and can include gas, water, steam and other resources. Reporting systems provide a timely flow of data, whether in printed or electronic report format, or as raw data for onward processing

Thermal Imaging

- Is a non-intrusive inspection of electrical and mechanical equipment while production continues.

- This data is then used to diagnose temperature problems, which may not otherwise have been detected until it is too late.

Electrical Examples

- Distribution Boards

- Busbar Connections

- Switchgear

- Phase Imbalance

Mechanical Examples

- Motors

- Conveyor Systems

- Pumps

- Bearings

For further information regarding any of the above services please contact us